Pleating and Pleat Assembly Equipment

-

AC17 Auto Compression Chamber

- Small footprint

- 30” max width and 36” max depth

- Fixed 1st operator position

- Adjustable 2nd operator position

- Linear bearings on all slides

- Belt infeed system

- Auto cycle compression chamber

- Easy change over

- 1” to 5” pleat production

- Set up for the 5 majors

- Other sizes available to quote

- 120v ac power and dry clean air required

- Lease to own application

-

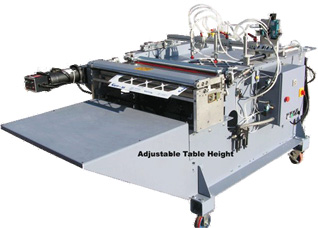

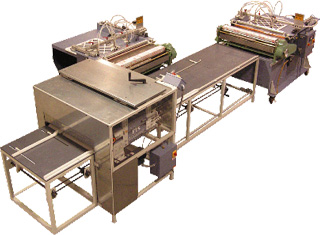

ASF-2 Tandem Auto Sheet Feeder/Gluer

- FTS Cold Glue Roll Coater included

- For 2 piece die cut

- Lift Table for automatic indexing of stack height

- Level compensators on vacuum system

- One vacuum generator per suction cup

- 120v ac power and dry clean air required

- Lease to own application

-

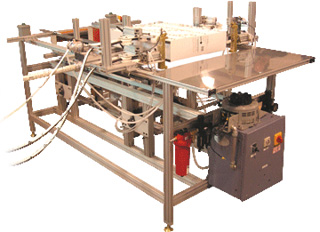

ASF-1B Auto Sheet Feeder/Gluer

- FTS Cold Glue Roll Coater included

- For 1 piece die cut

- Lift Table for automatic indexing of stack height

- Level compensators on vacuum system

- One vacuum generator per suction cup

- 120v ac power and dry clean air required

- Lease to own application

-

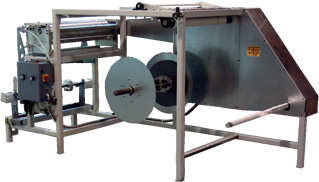

HML-300 Laminator (Hot Melt)

- 300 feet per minute (max speed dependent on materials and adhesive used)

- Variable Speed AC drive

- Clutched windup

- HMI touch screen

- Ramp up & down speed capabilities

- Programmable roll length

- Programmable Auto Shut Off

- Linear control of expanded metal on the fly

- Will run expanded metal, welded wire and some plastic nettings

- Pre-melter available

- 220v ac single phase power and dry clean air required

- Lease to own application

-

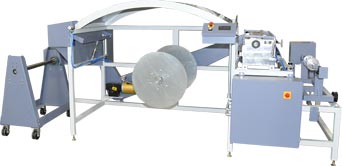

HML-150 Hot Melt Laminator

- 150 feet per minute

- 1 operator

- 240v ac, single phase

- Variable Speed AC drive

- Clutched windup

- Manual control of expanded metal on the fly

- Will run expanded metal, welded wire and some plastic nettings

- Lease to own application

-

RP-1 or RP-2 Rotary Pleater

- 200 pleats per minute

- 1 operator

- Available in 1 or 2 version

- 240v ac, single phase

- Variable Speed DC drive

- Lease to own application

-

PBP1-6 Pusher Bar Pleater

- Capable of producing 3/4 to 6 pleat height

- 60 Pleats per Minute on 1 (935 pleat packs per 8 hour shift)

- 20 Pleats per Minute on 4 ( 310 pleat packs per 8 hour shift)

- Manual Cut Off Knife ( Pleat Cutter available)

- Pleat Counter and Marker System

- 120v AC power and air required

- Lease to own application

-

Servo Pusher Bar Pleater 9PBP6

- 1 to 6 pleat depth range

- Our newest pleater that utilizes servo speed and precision along with an operator touch screen to deliver a machine that is faster and easier to change over than previous models of Pusher Bar Pleaters. Dry air required for this machine.

- Click Here for Demonstration Video

- Lease to own application

-

5" to 12" Pusher Bar Pleater

- 5-12 Pleater

- 18 Pleat Per Minute

- Auto Shut Off if Media Runs Out

- Lease to own application

-

Servo Pusher Bar Pleater 9PBP2

- 1" to 12" pleat depth range

- Our newest pleater that utilizes servo speed and precision along with an operator touch screen to deliver a machine that is faster and easier to change over than previous models of Pusher Bar Pleaters. Dry air required for this machine.

- Click Here for Demonstration Video

- Lease to own application

-

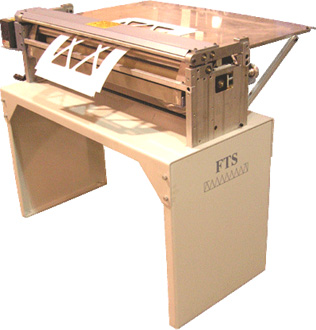

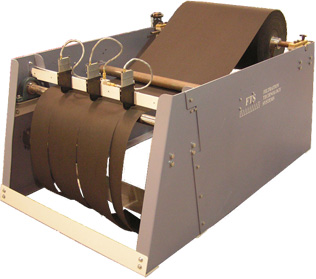

CGRC-2 Cold Glue Roll Coater

- 37 Wide Roller

- Variable Speed Drive

- Gear Driven not Belts

- Stainless & Aluminum Construction

- Uses Bearings not Bushings

- Comes with 2 Stainless Steel Pans

- Shown with Optional Stand

- Lease to own application

-

CC-1 Compression Chamber

- Can handle 1 to 6 pleated filters

- Pneumatic Anti-tie Down System

- 1 or 2 assemblers can supply one Compression Chamber

- Air required

- Set up for the 5 majors, 16x20, 16x25, 20x20, 20x25 & 24x24

- Can be placed at end of Pleat Assembly Line w/some modifications

- Lease to own application

-

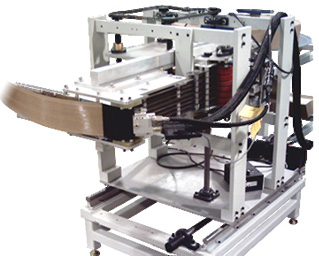

ASF-2 Tandem Auto Sheet Feeder

- 1 operator not including packaging

- Cold Glue Roll Coater included or we can use yours

- For 2 piece die cut (one piece die cut can be run with modifications)

- Click Here for Demonstration Video

- Lease to own application

-

ASF-1B Auto Sheet Feeder

- Cold Glue Roll Coater included or we can use yours

- For 1 piece die cut

- Lift Table for automatic indexing of stack height

- Click Here for Demonstration Video

- Lease to own application

-

PAL-1 Pleat Assembly Line

- 2-3 operators not including packaging

- Cycle time is operator based

- Can be used with Compression Chamber w/minor modifications

- Capacity of 1 to 5 pleat height

- For 2 piece die cut (one piece die cut can be run with modifications)

- Click Here for Demonstration Video

- Lease to own application

-

Pleat Assembly Group

- 2 Single Auto Sheet Feeders

- 1 Pleat Assembly Line

- For Machine Based Production

- Lease to own application

-

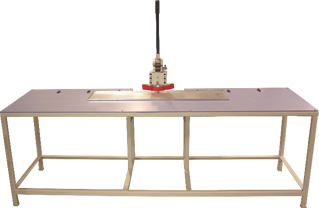

SAK-1 Pleat Cutter

- Adjustable cut depth from 2-6 nominal

- Pneumatic operation

- Removes V section of pleat

- Lease to own application

-

PFP-1 Pinch Frame Press

- 2 filters per minute x 4 Presses = 8 average on 20x20x1 size or 3,120 filters per 8 hour shift

- 1 operator per press x 4 Presses = 4 operators not including packaging

- Costly for making Non-Standards

- Makes Standard sizes

- Charge per die for additional size dies

- Capable of producing 1

- 2 piece Pinch style frame

- Glass, Synthetic, Pleats

- Change over times-30 minutes

- Lease to own application

-

LMS-1 Laminated Media Slitter

- 30 width

- 2 adjustable cutters

- Variable Speed Drive

- Click Here for Demonstration Video

- Lease to own application

-

LMS-36U Laminated Media Slitter/Unwind - 36"

- 36" width

- Pneumatic Slitters

- Easily Replaceable Blades

- Powered Anvil Shaft

- Pneumatic Brake on Unwind

- Click Here for Demonstration Video

- Lease to own application

-

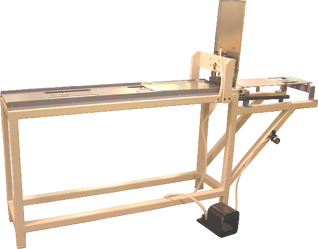

PSC-1 Pleat Spacing Conveyor

- To aid in the assembly of Rigid Filters

- Variable Speed Drive w/Foot Pedal

- Incline Rod Conveyor for Proper Spacing

- Hot Melt Unit with Handgun & Hose

- Lease to own application

-

GA-1 Foam Gasket Applicator

- Automatically applies Foam Gasket for 4 & 5

- Hot Wire cuts Foam at end of application

- Vacuum pick up for removal of release paper

- Click Here for Demonstration Video

- Lease to own application

-

CSN-1 Cell Side Notcher

- V-Notch for edge flange

- Adjustable edge guides & stops

- Lease to own application

-

CSB-1 Cell Side Bender

- Adjustable stops

- Set up for 12 with 6 adapters available

- Lease to own application

-

RCAT-1 Cell Assembly

- Adjustable Height Turntable

- Aids in Assembly of Rigid Filters

- Lease to own application

-

PSL-1 Thermal Pleat Spacing Line

- Automatically pick up pleats from an FTS Pleater and places in a lugged conveyor

- Conveyor maintains spacing

- Chipboard stock is then automatically attached via hot melt adhesive to pleat peaks, both top and bottom if needed

- Pleat pack can then be cut automatically

- Other FTS equipment can then be used to frame the pleat pack

- Click Here for Demonstration Video

- Lease to own application

-

EB-1 Edge Banding

- Edge Banding of Pleat Packs with Hot Melt Adhesive

- Can be Operated Independent of Pleater

- Different Width Adhesive Heads Available

- Lease to own application

-

ITW Melt Unit

-

AC15 Pleat Assembly w/Auto Feed Compression Chamber

- Small footprint

- Fixed 1st operator position

- Adjustable 2nd operator position

- Operators are always the same distance from filter regardless of size

- Linear bearings on all slides

- Belt infeed system

- Auto cycle compression chamber

- Easy change over

- 1 to 5 pleat production

- Set up for the 5 majors

- Other sizes available to quote

- Click Here for Demonstration Video

- Lease to own application

Our Services

As a leading producer of automation equipment, Filtration Technology Systems not only manufactures and designs filtration manufacturing equipment, pleating equipment, filter and filtration equipment, rotary pleaters, air filter production equipment and laminating equipment but also offers our customers consulting services, outstanding post production support and training.

- Product Support

- Professional Engineering

- Automation Equipment

- Custom Equipment Design

- Product Operation Training

- Custom Automation

- lease to own